A team of professionals

The more inventive we are,

the more solutions we can offer our customers.

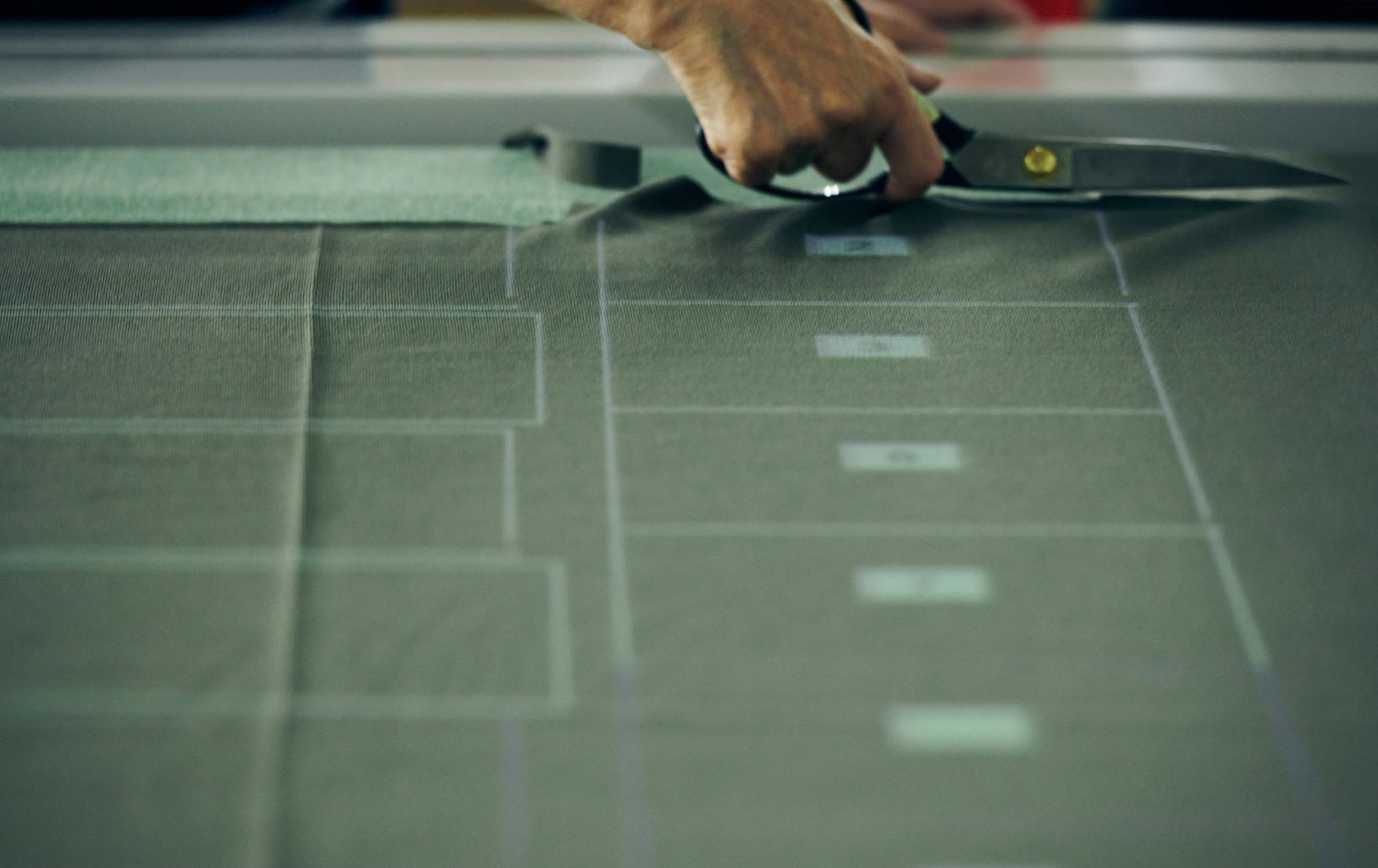

At ARTES, when it comes to manufacturing, we don’t give up. No matter how difficult a problem is, our professionals always try to find a solution. Let’s take piping, the process of trimming the cuffs and other edges of garments, as an example. Each brand has specific piping width and thickness requirements that need different types of attachments, such as a binder, on the sewing machine to match the type of fabric. This is because, unlike woven fabrics, knits tend to stretch and contract, and they shrink as soon as tension is applied during sewing. Because of these varying project requirements, it is not uncommon for sewing factories to refuse a request in terms of work efficiency. At ARTES, however, we tackle the problem by developing our own attachments. Our factories have a number of custom-made attachments developed for the brands we’ve worked with. Some of them are only used once, but we believe this is part of what it means to make clothes that respond to our customers’ needs. The more inventive we are, the more solutions we can offer to our customers. I find it very rewarding.

Takashi Hatakeyama

General Manager, ARTES AKITA

Small steps lead to trust and

reliability.

In a relay, the production and delivery management department would be the anchor runner. As production moves through cutting, sewing, and finishing, we are responsible for the final leg, where we hand over the baton to our customers who are waiting at the finish line. Even if the sewing is done beautifully, if we find a small flaw in the fabric during shipment, the product cannot be sold. We also know that if we miss even a single item in our delivery, it can cause problems for our customers. Our inspection and delivery processes are extremely thorough, knowing that how we handle these final steps has a great impact on our customers’ businesses.

At ARTES, our teams are required to thoroughly inspect every item to ensure there are no defects in the fabric and parts. We cross-check the number of packaged items with their shipping vouchers before dispatching to make sure there are no discrepancies. These steps may seem obvious, but it is the accumulation of these small efforts that eventually lead to trust and reliability.

Our sincere and diligent efforts have been recognized by our customers, including a fashion business that presented us with a special award. There have also been times when customers who moved their production overseas have come back to us because they feel that ARTES is the only reliable choice.

Tomokazu Kato

General Manager, ARTES HAKODATE

Striving to be a helpful manufacturing partner our

customers can rely on.

If a customer gives us a problem where the perfect score is 100, how can we come up with a solution that scores 105 or more? The work of ARTES’s sales and marketing department is exercising creativity and moving our feet to surpass our customers’ expectations. Many people are involved in the creation of clothing, including fabric suppliers, subcontractors, pattern makers, and factory staff. In order to assure Made by ARTES’s quality at every step of the process, we take on the role of overseeing the entire project.

For example, if there is a possibility that dyeing may cause the color to bleed onto the fabric, we inform our customers beforehand during the proposal stage. We also keep a close eye on the samples and products delivered from the factory to make sure that they are in line with the style of the brand. We are confident that we have more experience and knowledge than most others because we are involved in the entire process, taking responsibility for everything from the initial meeting to production and delivery.

ARTES can help you solve problems. We will continue to be a manufacturing partner our customers can rely on.

Yasuo Takahashi

Managing Director

Anticipating needs by being in sync with our customers.

Our goal is to accurately capture the designer’s intentions and creating the image they envisioned. The success or failure of the clothes-making process depends on the skills of the pattern maker. OEM manufacturers commonly assign different pattern makers for every project or subcontract the work to other companies. At ARTES, however, a pattern maker works with a brand on a long-term basis. The longer we work with a brand, the more familiar we become with its style, which allows us to provide solutions that are specifically tailored to its needs.

For example, the position and type of tags vary from line to line, even within a single brand. If there is a different pattern marker for every project, knowledge needs to be shared and handed over every time, which reduces efficiency and risks information being lost during communication. Having one pattern maker who knows the brand inside and out eliminates this risk and allows for smooth communication with the factory.

ARTES understands without you having to explain. We listen to our customers every day as we aim to create clothes with the spirit of being in sync with their needs.

Yoko Kudo

Chief Pattern Maker